By NICKY MANN, 2014 Australian Nuffield Farming Scholar

First of all, this whole study topic couldn’t have been undertaken without the wonderful and generous support of my investors Horticulture Innovation Australia and Nuffield Australia.

Therefore, I am eternally grateful and indebted. I would also really like to encourage other growers in the Protected Cropping Industry to seriously consider applying for a Nuffield Scholarship as it is a life-changing experience and adds so much value to agriculture here in Australia and across the globe.

Not only do you get to travel to some amazing countries which will force you completely out of your comfort zone but you get to meet truly extraordinary people, learn phenomenal things, see mind-blowing farms / research / businesses, but you get to share and collaborate with other likeminded people around the world which only adds benefit and substance to relationships which are crucial in this fast changing world we live in and will assist humanity to adapt and to progress.

Why did I undertake this study?

As hydroponic rose growers based on the Central Coast, we have managed to cushion ourselves from market pressures by opening our own retail outlets, being vertically integrated and have added agritourism to the mix in order to survive as a small grower in the protected cropping industry.

However, with the continued surge in imported roses from both South America and Africa landing on Australia’s shores increasing the squeeze on prices. Wade and I decided to diversify and spread our risk even further from just being rose growers.

We needed to grow a high value crop in our multi-span twin-skin greenhouses and felt we had to consider growing “food/fruit” as opposed to decorative fun-fair as consumers are more concerned about what they eat and where it is grown than where their flowers are grown which will sit on a vase in their home and not be consumed.

Enter the Nuffield Scholarship – which I decided to use to learn / study all the ins-andouts of intensive production of berries using greenhouses, substrates and hydroponics.

I need to add here it was a case of learning by doing too as we received our first raspberry plants in November 2013 a mere two months after I received my scholarship. The blueberries arrived six months later.

What were my objectives of this study?

- Overview the berry industry in Australia and abroad, looking at;

- Protected Cropping Structures

- Containers and Substrates

- Hydroponic systems

- Compare the pros and cons of protected cropping vs traditional growing methods

- Analyse the major berry crops like strawberries, blueberries, raspberries and blackberries

- Formulate a recommendation to growers in the Australian industry considering intensive berry production in greenhouses with substrates and hydroponics

Overview of the Berry Industry

The above graph gives a fairly accurate overview as to where berries stand on the global market becoming the number one fruit category by value in the USA and having 4.2% growth year on year.

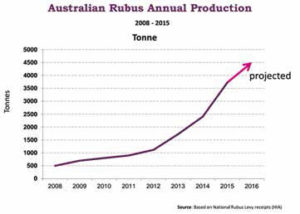

Here in Australia Rubus (Raspberries, Blackberries, Boysenberries, etc) have grown in production and consumption from less than 500 tonnes in 2008 and will exceed 4500 tonnes in 2015 as shown in the graph below.

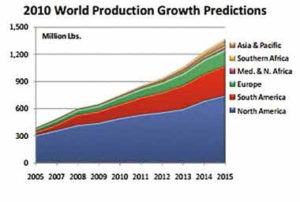

Blueberry production and consumption in Australia like the rest of the world has seen incredible growth with no signal of demand or production plateauing or slowing plus the saturation point is not looking like it is anywhere in sight in the near future – shown in Cort Brazelton’s graph below.

Therefore, with the trends in berry consumption and demand continuing to rise – it feels right to consider all options available to growers to increase production to meet the continued demand.

Protected Cropping Structures

I was lucky enough to travel to 11 countries and managed to see all sorts of berry production from wild low-bush blueberry production in Nova Scotia, Canada to high tech glass venlo strawberry production in The Netherlands.

When it came to putting protection over berries the range was vast and included basic bird-netting, hail netting, low-tech “Spanish-style” tunnels, higher tech tunnels, multi-span greenhouses, venlo glasshouses as well as retractable plastic, glass and polycarbonate structures.

Obviously the more protection and sophistication reflected in better climate control but so too price.

The growers and projects I visited all had very good reasons why they had selected the particular structure they were growing the berries in and were in most cases getting the best results for the money invested. Yes there are pro’s and con’s for every structure but in most cases the decisions were purely economic.

Substrates

Being a fan of coco-peat from years of growing roses in this media, it was encouraging to see how widely this media was being adopted by hydroponic berry growers with much success and I would hasten to say this was by far the most popular.

However, again I saw growers using sawdust, sand, bark, potting mixes and then combinations of the aforementioned – some with great success.

However, my concern would be in a couple of years when the sawdust and bark particularly breaks down and how this will impact the plant health and fertigation feeds.

It was exciting to see growers starting to experiment with blends like coco-peat, peat moss and mycorrhizae for blueberries and coco-peat with Trichoderma for raspberries.

It is important to have a low pH for blueberries and to have good aeration for raspberries as these plants are prone to root diseases.

My preference for berry crops is coco-peat as it is organic in nature and therefore biodegradable, has high water retention capacity, high air porosity and is a renewable source of growing media.

I was lucky to be shown extensively around Legro in The Netherlands and learnt so much about coco-peat, peat moss, buffering and blends.

After growing in coir for nearly 12 years it was refreshing to be put straight on some of the myths I have been lead to believe with regard to coir.

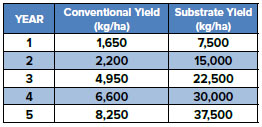

The following table demonstrates clearly the advantage of using substrate as a growing media for blueberries and leaves little doubt in one’s mind to difference in production between the two methods of cultivation.

Basically, after 5 years 8.25 Tonnes vs 37.5 Tonnes which equates to 450% increase in yield by using substrates.

Basically, after 5 years 8.25 Tonnes vs 37.5 Tonnes which equates to 450% increase in yield by using substrates.

Comparative Results with “Aurora” (Northern Highbush Blueberry Variety) by Peter van Dijk, Blueberry Consultant – The Netherlands, March 2015

Containers

I discovered as most people know farmers and growers are extremely innovative and resourceful especially when it comes to hydroponic production and using different types, shapes and forms of containers to grow in.

Grow bags/pillows of coir are extremely popular and regularly used especially by hydroponic strawberry growers on table tops.

The real downside to bags is getting rid of all the plastic after it’s use – this is a tedious process and expensive to do.

I saw the best results for strawberries in long-shallow white troughs really heaped high with coco-peat so that the strawberries could be planted at a slight angle to present the fruit for easy picking.

Square 10l pots with excellent aeration for raspberries and large 40l poly-weave grow bags (Garden City Plastics) for blueberries seemed to me like the best options.

I think the new range of pots from PlantLogic have some exciting potential for the hydroponic berry production and should be investigated by growers considering this type of production.

Protected Cropping Berry Pro’s

- Increase plant density

- Improved and effective use of IPM in a confined environment

- Increased first class saleable fruit

- Protection against birds and pests which means less damaged or spoilt fruit

- Protection against rain, hail, wind means less disease and less sprays

- More efficient and effective use of labour as labour can work in all weather conditions

- Higher yields and sooner

- Less RISK of crop loss due to disease, rain, birds, wind, pests

- Faster growth and faster production of fruit – multiple fruiting cycles per season/year

- Change varieties more regularly – keep up-todate with latest genetics

- More control of the plants can change feeds quickly to be generative or vegetative or stress plants to induce flowering. Substrate is very even compared to soil in large areas

- Close irrigation systems – recycle water/nutrients

Protected Cropping Berry Con’s

- High cost – and the better the structure the more investment involved

- Air movement – heat in tunnels can be too hot not good for plants, labour or pollination

- Wind and hail damage to the plastic covers or glass can be disastrous

- Plants have to be replaced more regularly

- Machinery harvesting is limited as machines cannot fit inside structures easily

- Substrate is less forgiving than soil as a media for growing anything in therefore irrigation and fertigation must be precise

- Plastic film can be inhibiting for the best performance of pollinators

- Dust and spray residue can accumulate on the leaves of plants in tunnels which slows down rate of photosynthesis which affects plants performance

- Need relatively level land to build greenhouses and tunnels substrates

Greenhouse strawberries

High tech production of strawberries seen in The Netherlands, Belgium and Ireland using the latest glass venlo glasshouse structures was extremely impressive and matched some of the finest high tech tomato, capsicum and cucumber projects I have seen around the world.I think it is only a matter of time before the majority of strawberry production comes into high tech protection as it produces consistent quality and supply which the supermarket and consumers LOVE.

High tech production of strawberries seen in The Netherlands, Belgium and Ireland using the latest glass venlo glasshouse structures was extremely impressive and matched some of the finest high tech tomato, capsicum and cucumber projects I have seen around the world.I think it is only a matter of time before the majority of strawberry production comes into high tech protection as it produces consistent quality and supply which the supermarket and consumers LOVE.

Strawberry Wish List

- High – tech glasshouse

- Using bumblebees * in conjunction with honey bees for ultimate pollination

- Costs = A$450 per m²

- 15 year return on investment

- 15kg per m²

- Closed irrigation system

- Vents

- Shade-screens

- Energy screens

- Pipe and rail system

- Hydronic heating and buffer tanks

- CO₂ injection

- Hanging gutters/suspended single table tops

- Troughs filled and mounded with coco-peat

- 2 support wires

- Foggers and misters

Greenhouse Blueberries

Although most greenhouse blueberry production currently being done around the globe is in low tech “Spanish-style” tunnels like the ones sold by Haygrove.

This type of protection is effective but does have it’s drawbacks like trapping heat and slowing airmovement, but it is economically viable.

However, there is a slight trend to use a more sophisticated multi-span greenhouse with more climate control features.

It is still early stages and the profitability of this slightly more expensive infrastructure has not been established yet.

Blueberry Wish List

- Retractable roof and side vents for climate control i.e. exhaust heat and humidity and to assist the pollinators

- 40 ltr poly weave bags

- Coco-peat, Irish peat moss, perlite and Mycorrhizae

- A$100 per m²

- Yields:- 1kg per plant 1st year

3kg per plant 2nd year,

5kg per plant 3nd year

10kg per plant thereafter - Bending, pinching and pruning system

- Closed irrigation system

- Shade-screens

- Bumble bees* and honey bees for pollination

- T-system support wires – 30cm interval

- Foggers and misters

Greenhouse Raspberries (Rubus)

High tech production of raspberries seen in The Netherlands, Belgium and Ireland using the latest glass venlo glasshouse structures was extremely impressive and advanced.

I would love to see this type of production undertaken in Australia but remain doubtful it will happen anytime soon as there is fairly good production and quality of raspberries coming out of tunnel production currently and uncertain whether growers will undertake the huge investment required for what is a relatively small market in Australia. However, my wish list would be:-

Raspberry Wish List

- Coco-peat blend with Trichoderma

- 10 ltr pots with good aeration at base like a PlantLogic 10l raspberry pot; black square pots for cold climates and white pots for warm climates.

- Costs – A$100 per m²

- Double cropping of primo-canes in 1st year

- Yields of 2kg per plant

- 20 tonnes first class fruit

- 3 stem system in linear trellising

- Multi-span plastic structure

- Closed irrigation system

- Retractable roof and side vents for ultimate pollination by bees and to exhaust heat and humidity

- Shade-screens

- Bumble bees* and honey bees for pollination

- Potential to adopt high-wire greenhouse cucumber and capsicum growing system

* Bumblebees are not available on mainland Australia unfortunately & not allowed to be commercially reared in Tasmania.

Nuffield Key Findings

- Timing – everyone using protected cropping and hydroponics was totally focused on particular timings of their crops either early, late or without interruption; or very particular supply gaps

- Minimising risk – ensuring all fruit was reaped and no losses were incurred from disease, pests, climate or labour not being able to work

- Consistency of supply and quality

- Efficient and effective use of labour

- Water and nutrient saving

Farming land is limited and this method means berries can be grown anywhere due to the use of substrate and protective structures i.e. roof tops

Unexpected Findings

- Methyl bromide is still used in USA as a soil fumigant for soil grown strawberries, blackberries and raspberries – this is being phased out and growers will have to find alternative methods to sterilize their soil OR move to substrates

Spotted Wing Drosophila (SWD) – this is the plague of USA, South America and Europe – this pest is literally wiping out entire crops of berries. Protection helps especially the more sophisticated the crop protection. - Control of genetics by a few powerful breeders and marketing companies

- Honey bees as pollinators were used in conjunction with bumble bees in high tech greenhouses – growers found that when they were effective there was nothing better than honey bees. Plus they were cheaper as there are more bees in a honey-bee hive and they are gentle and highly effective CROSS pollinators. Honey bees don’t like to work when temperatures fall below 15°C and when humidity climbs above 71%, which creates a distinct window.

- How well raspberries travel from South Africa to United Kingdom – yes, if Australian Rubus growers think they are safe from imported soft fruit like raspberries being imported into Australia – think again. South Africa air freights raspberries to Europe with much success and without loss of quality or shelf-life. So if market access changes Australian producers can be under pressure. This could also be an opportunity for our growers to export our fruit to foreign markets.

- Controlled Atmosphere (CA) Storage – bulk refrigerated containers of controlled atmosphere storage of blueberries is already being done from South America to Europe – again this is a threat to Australian growers but so too a huge opportunity for our blueberry growers to export our “clean-green” Australian produce abroad.

Recommendations

- Protected cropping minimises the risk from crop loss due to birds, pests, disease, rain, wind, hail, and not being able to work on the berry crop

- Diverse berry crops for the health of the pollinators

- Invest in knowledge – learn, share and collaborate as one united Australian berry industry

- Market access can change overnight and Australia must be prepared for this and should be establishing alternate or export markets nowFinally, a big thank-you to the numerous growers/ farmers, researchers and fellow Nuffield scholars for your time, help and inspiration for this study – I am truly indebted to you all and hope the berry and protected cropping industries will find benefit from my study topic.

Lastly to my family and employees at Roses 2 Go Pty Ltd thank-you for your continued support throughout this journey.

If you would like to read the in depth findings and details of my study – my Nuffield report is pending publishing and will be available to read from the Australian Nuffield website.

For more information

Nicky Mann

nickymann125@gmail.com