Dr Sukhvinder Pal (SP) Singh

Program Leader- Fresh Produce Safety and Traceability

NSW Department of Primary Industries and Regional Development

E: sp.singh@dpi.nsw.gov.au; M: 0420 593 129

On 12 August 2022, Food Standards Australia New Zealand (FSANZ) developed new primary production and processing (PPP) standards for berries, leafy vegetables and melons. Three new standards have been included in the Australia New Zealand Food Standards Code:

- Standard 4.2.7 – Primary Production and Processing Standard for Berries

- Standard 4.2.8 – Primary Production and Processing Standard for Leafy Vegetables

- Standard 4.2.9 – Primary Production and Processing Standard for Melons

The standards aim to strengthen food safety management on-farm and during initial processing to reduce food safety risks along the supply chain from farm to fork.

The new requirements will take effect from 12 February 2025.

If you grow/harvest and pack/process leafy vegetables, berries and melons, new PPP standards will apply to your business. Further information is available at the following web links:

https://www.foodstandards.gov.au/business/food-safety-horticulture

FSANZ has developed a guidance for PPP Standards for horticulture https://www.foodstandards.gov.au/publications/safehorticultureaustralia

The Safe Leafy Veg Project: Microbial food safety risks in leafy vegetable production in protected cropping systems

Since April 2023, the Safe Leafy Veg project (VG22002) has been investigating potential sources and routes of microbial contamination in the leafy vegetable production and postharvest systems. Both field and protected cropping systems have been covered under this project.

Are protected cropping systems invincible to microbial food safety risks?

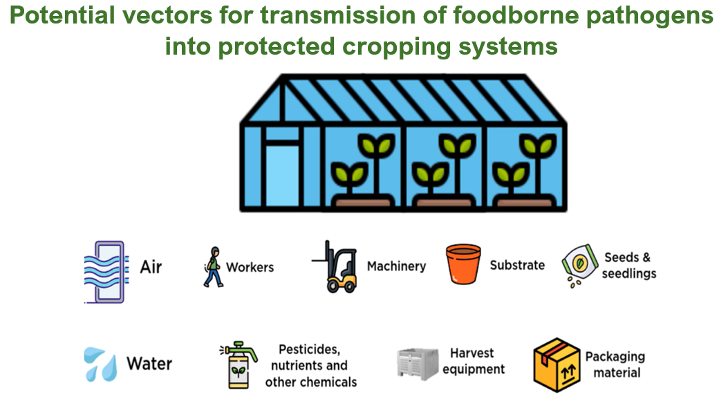

The answer is “No”. There are several elements common to field and protected systems which can potentially introduce microbial contamination such as air, water, seed, nutrients, pesticides, machinery, equipment and workers. The field production systems have external factors such as extreme weather, birds, animals and soil which could lead to a higher risk of microbial contamination. On the other hand, protected cropping systems are equally prone to microbial contamination if preventative control measures are not effective. Contaminated substrate, water, workers and machinery along with ideal indoor climatic conditions (temperature and humidity) provide congenial conditions for microbial proliferation and persistence.

Figure 1: Potential vectors for transmission of foodborne pathogens into protected cropping systems

For example, cucumbers grown in a greenhouse caused a multi-state Salmonella outbreak in December 2022 in Australia. Leading protected cropping suppliers in North America have been regularly implicated in foodborne illness outbreaks linked to fresh produce grown in protected systems. It is therefore important to consider the sources and routes of microbial contamination in protected cropping systems.

Major sources and routes of microbial contamination should be examined with the following as primary considerations:

- Water (source, filtration, treatment and sanitisation)

- Substrate/growing media and nutrients

- Workers (health, PPE, and hygiene)

- Seeds and seedlings

- Machinery

Multiple research studies have shown that foodborne pathogens such as Salmonella and Listeria monocytogenes can survive and reproduce in hydroponic solutions. These pathogens are able to contaminate edible parts of produce grown in hydroponic systems.

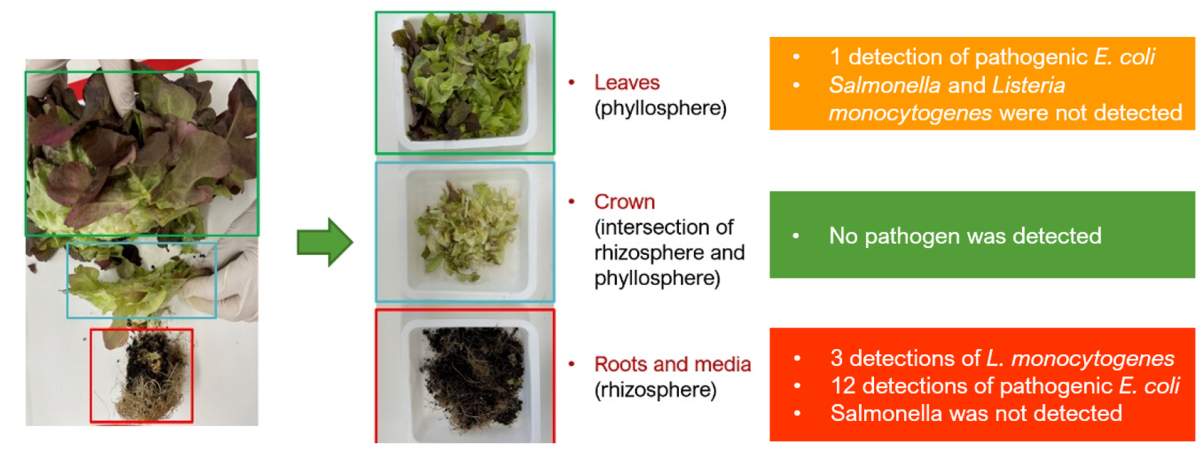

As part of the Safe Leafy Veg, we were interested in determining the nature and magnitude of microbial risks in hydroponically grown leafy vegetables. We collected 50 samples of lettuce and herbs (sold with rootball or potted) from retail stores in May 2023 and analysed for target pathogens: Salmonella species, Listeria monocytogenes and pathogenic E. coli. Each sample was divided into three parts- leaves (phyllosphere), crown (intersection of phyllosphere and rhizosphere) and roots and media (rhizosphere). The results showed one detection of pathogenic E. coli in an edible leafy part while 3 detections of Listeria monocytogenes and 12 detections of pathogenic E coli were recorded in roots and media sections of samples (Figure 2). This dataset is indicative of contamination of hydroponic systems with these pathogens.

Figure 2: Detection of target pathogens in different parts of hydroponically grown leafy vegetables.

Environmental monitoring plan

Protected cropping facilities should have an environmental monitoring plan similar to processing facilities to verify the effectiveness of control measures, including cleaning and sanitisation. Regular microbiological testing of water, produce, hydroponic channels, floors and drains would provide an early indication of the entry of pathogens in growing facilities.

Figure 3: Project team collecting environmental swabs from a greenhouse facility where drains tested positive for pathogenic E. coli.

Management approaches

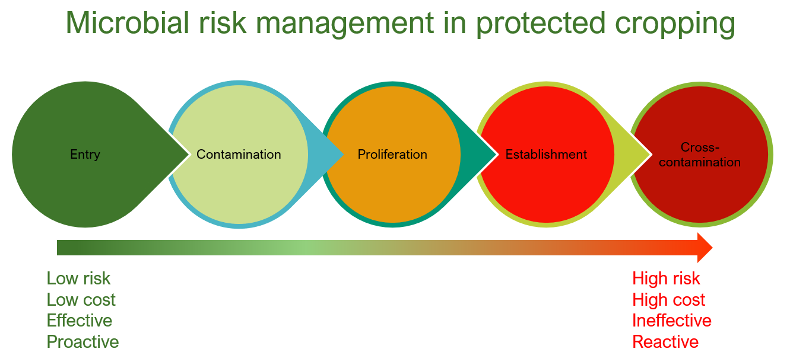

Food safety risk management in protected cropping system should focus on preventing the “ENTRY” microbial contaminants in the production systems (Figure 4). Once these pathogens enter the system, they “CONTAMINATE” produce, machinery and infrastructure. Upon contamination, these pathogens multiply or “PROLIFERATE” very fast and “ESTABLISH” themselves in the facilities by forming biofilms in hydroponic systems, surfaces and floors. After establishment, these pathogens are difficult to get rid of with routine cleaning and sanitisation procedures and these become a source of “CROSS-CONTAMINATION”.

It is recommended that protected cropping growers should focus on preventive approached which are low-risk, low-cost, effective and proactive while management approaches to decontaminate production systems are high-risk, high-cost, ineffective and reactive in nature.

Figure 4: Microbial risk management in protected cropping systems

Food safety helpdesk

As part of this project, a food safety helpdesk service is offered to growers, packers and supply chain partners to address technical enquiries on food safety. This does not involve any commercial product trials and endorsements. Contact Dr SP Singh, sp.singh@dpi.nsw.gov.au; M: 0420 593 129

Get involved

Over 80 leafy vegetable growers are onboarding this project through their engagement with the project team by seeking solutions to food safety process improvement and compliance issues. The project team is calling growers and processors to participate in the project by sharing their food safety practices, be a part of the irrigation water quality or soil amendments trials and learn more about data-based food safety risk management. The project team maintains confidentiality and privacy of all participants and presents and uses data in aggregated and anonymised form for industry-wide food safety practice improvement.

Contact details:

Dr Sukhvinder Pal (SP) Singh

Program Leader- Fresh Produce Safety and Traceability

NSW Department of Primary Industries and Regional Development

E: sp.singh@dpi.nsw.gov.au; M: 0420 593 129